Questions about our goals or process?

A New Solution for

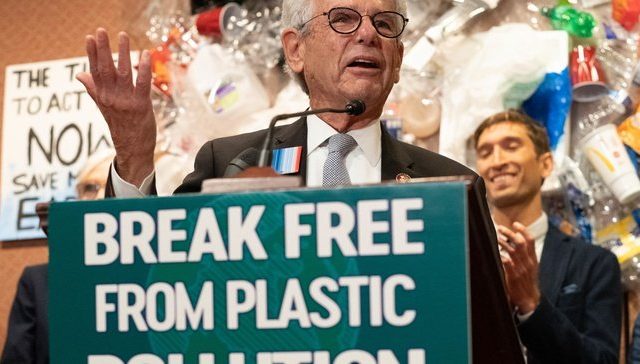

Reducing Plastic Waste

Our goal is to remove as much plastic waste as possible from our planet and reduce greenhouse gas production, making our world safer for you and your community.

Our solution is to divert plastic wastes from landfills and process them in biochemical refineries to produce commodity biochemicals.

Our Advantages

The Southeastern Biochemicals Advantage:

Plastic is food for our microorganisms

Our approach is to consider that if all types of plastic waste can be made into food for our microorganisms, then all of the types of plastic currently optimized for their specific use need not be replaced or re-engineered to be biodegradable.

In most recycling processes, the goal is to reproduce the original plastic from waste (i.e., produce recycled or rPET from PET). In our processes, the goal is to use all types of plastic waste as food for microorganisms that produce different products unrelated to the original type of plastic, thus greatly increasing the number of products that can be produced from plastic waste.

No separation required

Our hybrid chemical-biological process simultaneously processes different types of plastic waste, thus eliminating the need for separating the plastics before processing them. Where current recycling methods toss out plastic of mixed types or those contaminated with food, our process works without those restraints. As such, we have the capacity to keep a greater breadth of materials out of our landfills and oceans. This advantage addresses the current Extended Producer Responsibility legislation being considered by State and Federal governments.

Nearly 100% outputs have commercial value

Our products include fatty acids, glycerin, and other even more valuable products. These chemicals are used in the manufacture of detergents, lubricants, paints, cosmetics, tires and other markets and as building blocks to produce other higher value chemicals (dicarboxylic acids, lactones, etc.). Nearly 100 percent of the process outputs have commercial value.

Biological treatment helps our environment

Biological treatment can make the manufacture of products more sustainable. For example, palm oil is the feedstock for fatty acids and alcohols. Use of plastic waste to produce these products will not only divert plastic from our landfills but will also reduce the demand for palm oil. Palm groves are planted in SE Asia by deforesting the land which has a negative impact on our environment.

We Are Experiencing a Global Plastic Pollution CrisisThe Problem

In 2018, the world produced more than 395 million tons of plastic, tripling its production from 1990. And there is every indication that this trend will continue to increase. The World Economic Forum predicts that plastic production will double over the next 20 years.

Our current solution for plastic waste is not working. In recent years only 9% of plastic used in the United States is actually recycled. An additional 15.5% is burned in incinerators, increasing air pollution. The rest of the plastic waste goes into landfills where it can take over 500 years to decompose or it is discarded with over 8 million tons making its way to the oceans each year. That is equivalent to a garbage truck full of plastic dumped into the ocean every minute.

We need a better approach to managing our plastic waste.

An Innovative Approach to Reducing Plastic WasteOur Solution

At Southeastern Biochemicals, our solution is to produce biochemical products with higher commercial value than plastic waste, resulting in profitable and sustainable solutions. We use a unique hybrid chemical-biological process to convert plastic waste into fatty acids, glycerin and high-value chemical derivatives used in consumer markets including personal care and cosmetics, soaps and detergents, lubricants, greases, tires, and in the coatings and resins markets.

Grounded in science, engineering, and business, Southeastern Biochemicals seeks to first construct and operate a commercial-scale, proof-of-concept, biochemical refinery and then expand operations throughout the United States.

Please contact us if you would like to learn more about our vision.

Questions about our solutions to plastic waste?

WORKING TOGETHER TO ACHIEVE RESULTSOur Partners

Georgia State University

Southeastern Biochemicals’ proprietary technology was developed from the work of Eric Gilbert, Ph.D., associate professor of biology at Georgia State University. Southeastern Biochemicals is the exclusive optionee of the Georgia State University Research Foundation’s intellectual property rights in the technology. To learn more about Dr. Gilbert’s exciting research, please see the Georgia State University Research Magazine article in our Related Articles section.

Contact Us

Copyright: 2020 Southeastern Biochemicals. All Rights Reserved.

Designed by: Greene Street Designs